Automatic Back Flush Technology

New Automatic Back Flush video

An elegant and simple method of protecting heat exchangers from the detrimental effects of fouling of the heat transfer surfaces has been developed for systems where one of the heat transfer fluids is routinely consumed or “made-up”, (e.g., district heated potable water or solar heating systems): .

Background: The Consequences of Heat Exchanger Fouling

Heat exchanger scaling/fouling is a major concern for both manufacturers and end users from a performance, reliability, and maintenance perspective. Fouling of a heat exchanger occurs when deposits of unwanted materials present in a heat transfer fluid build up on heat exchanger surfaces, limiting heat transfer rates and restricting flow passages. The presence of minerals, corrosion products, or biological growth in the heat transfer fluids are all symptoms that cause fouling. The degree to which fouling impacts performance varies considerably depending on the nature of the fluids being handled and the mechanisms in place to prevent it.

During fouling, "unwanted" material is deposited on heat-transfer surfaces, increasing the resistance to heat transfer, and resulting in a reduction of the overall heat-transfer coefficient. Fouling also causes a reduction in the flow passage areas that leads to an increased pressure drop and pumping power. In addition, the fouling of heat heat exchangers can also lead to:

During fouling, "unwanted" material is deposited on heat-transfer surfaces, increasing the resistance to heat transfer, and resulting in a reduction of the overall heat-transfer coefficient. Fouling also causes a reduction in the flow passage areas that leads to an increased pressure drop and pumping power. In addition, the fouling of heat heat exchangers can also lead to:

- Increased capital cost for larger equipment required to compensate for reduced heat-transfer rates;

- Additional energy for increased pumping (or reduced flow rates);

- Lower thermodynamic efficiency in heating and cooling equipment;

- Higher maintenance costs for anti-foulants, chemical treatments and cleaning of fouled surfaces;

- Loss of revenue or utility due to servicing shutdown periods

Systems That are Prone to Fouling

Fouling of heat exchangers is most prevalent in systems where one or both of the heat transfer fluids is consumed or routinely “topped up†from a supply that may contain elements that will foul heat exchanger surfaces.

An obvious example is a hot water heating system where potable water is consumed for use in a process or for domestic consumption. Such conditions are common in “indirect†freeze protected solar hot water heating systems, domestic hot water heating from district heating systems, or the indirect heating of thermal energy storages by boilers or heat pumps.

In these cases, while fluid properties can usually be controlled on the closed primary (heat-source) side of a heat exchanger, significant fouling may occur on the potable water side of the heat exchanger depending on the composition of the water supply.

An obvious example is a hot water heating system where potable water is consumed for use in a process or for domestic consumption. Such conditions are common in “indirect†freeze protected solar hot water heating systems, domestic hot water heating from district heating systems, or the indirect heating of thermal energy storages by boilers or heat pumps.

In these cases, while fluid properties can usually be controlled on the closed primary (heat-source) side of a heat exchanger, significant fouling may occur on the potable water side of the heat exchanger depending on the composition of the water supply.

While cleaning of certain heat exchangers may be practical in industrial applications, it is often too costly in residential installations or impractical with the current class of compact heat exchanger (e.g., brazed plate heat exchangers).

As heat exchangers become increasingly more efficient and compact, fouling may severely limit the life, or performance, of thermal systems. This may limit their applications and diminish their availability as high performance, low cost heat transfer solutions.

Fortunately, in applications where the secondary fluid is consumed (e.g., potable water heating, etc), a simple and reliable solution is available to eliminate fouling. Passive anti-fouling is described below.

As heat exchangers become increasingly more efficient and compact, fouling may severely limit the life, or performance, of thermal systems. This may limit their applications and diminish their availability as high performance, low cost heat transfer solutions.

Fortunately, in applications where the secondary fluid is consumed (e.g., potable water heating, etc), a simple and reliable solution is available to eliminate fouling. Passive anti-fouling is described below.

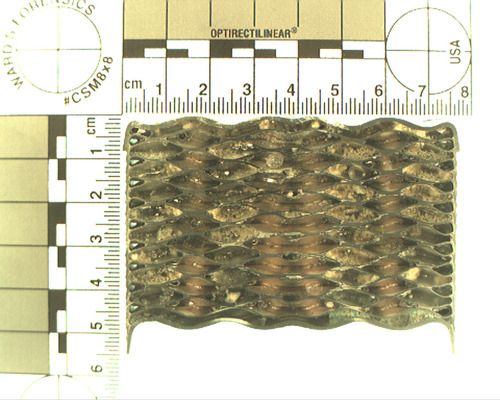

A cross section of a compact brazed plate heat exchanger taken from a residential water heating system after one year of operation. Even after just one year, the flow channels are completely clogged with mineral deposits.

Standard Approaches for Controlling Heat Exchanger Fouling

To combat fouling in large commercial systems, the chemistry of heat transfer fluids is carefully controlled and routinely checked. If fouling occurs, aggressive mechanical or chemical cleaning operations are used to bring the heat exchanger back to peak performance. To facilitate cleaning, commercial heat exchangers are often constructed such that they can be routinely disassembled for cleaning as shown (e.g., clamped plate heat exchangers). These operations often involve disassembly of the unit resulting significant “down times” and expense.

An alternative arrangement that has been implemented on large industrial heat exchangers is to back flush heat exchangers by reversing the flow direction of the heat transfer fluid at routine intervals. This process “flushes” out deposits accumulated on heat exchanger surfaces. While effective in many cases, it requires automated reversing valves that are expensive and potentially unreliable.

In certain cases, if the buildup rate of wanted material is slow, system designers will increase the capacity of a heat exchanger to compensate for the reduction in performance, which leads to increased cost and an oversized system.

An alternative arrangement that has been implemented on large industrial heat exchangers is to back flush heat exchangers by reversing the flow direction of the heat transfer fluid at routine intervals. This process “flushes” out deposits accumulated on heat exchanger surfaces. While effective in many cases, it requires automated reversing valves that are expensive and potentially unreliable.

In certain cases, if the buildup rate of wanted material is slow, system designers will increase the capacity of a heat exchanger to compensate for the reduction in performance, which leads to increased cost and an oversized system.

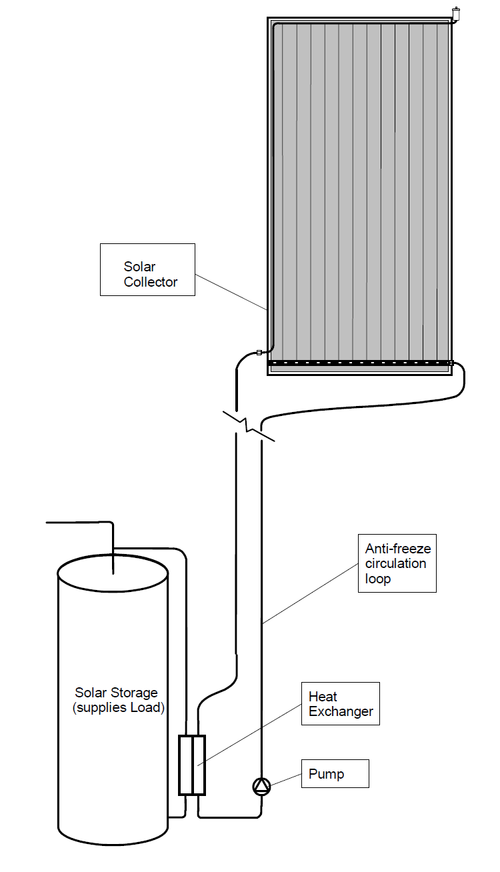

Example Application: Passive Anti-Fouling for Solar DHW Systems

Solar domestic hot water (SDHW) systems are one of the most cost effective ways to utilize solar energy. In climates where there is a potential for freezing conditions, an anti-freeze solution is usually used to transfer heat from a solar collector to a hot water storage through a heat exchanger. Potable water is circulated through the tank-side of the heat exchanger by thermosyphon (i.e., buoyancy induced flow) or by a secondary pump. These types of systems often use low flow rates through the heat exchanger to enhance thermal stratification in the storage tank (see the discussion in the NCHE page), which may be prone to fouling or complete blockage due to the accumulation of sediments, scale and mineral deposits. In addition, there is a high probability that mineral salts and other impurities may be present in the potable water supply in many locations. In these cases, fouling of the heat exchanger may occur if the device is not routinely cleaned or flushed of accumulated matter. (The mechanisms of heat exchanger fouling are described in a separate document attached).

While it is common practice in large commercial systems to routinely disassemble and clean components to minimize fouling effects, in residential installations this is not practical due to the associated costs. In these cases, other means must be used to minimize fouling effects.

In response to this need, a passive back-flushing system that can be installed on the water supply to the heat exchanger was designed. This device allows the heat exchanger to be routinely back-flushed many times a day. The action becomes a normal operation of the system and does not require user intervention, external power or controls to function.

While it is common practice in large commercial systems to routinely disassemble and clean components to minimize fouling effects, in residential installations this is not practical due to the associated costs. In these cases, other means must be used to minimize fouling effects.

In response to this need, a passive back-flushing system that can be installed on the water supply to the heat exchanger was designed. This device allows the heat exchanger to be routinely back-flushed many times a day. The action becomes a normal operation of the system and does not require user intervention, external power or controls to function.

How Does it Work?

The operation of the Automatic Back Flow device (ABF) during normal operation (i.e., solar charging), hot fluid from the solar collector heats the potable water in a "side-arm" heat exchanger, causing it to circulate from the bottom of the storage tank to the top. This configuration ensures that the hot water is delivered to the top of the storage where it can be directed to users. During this time, the heat exchanger surfaces on the potable water side are prone to fouling by "inverse soluble salts" that will precipitate on the heat exchanger surfaces.

To prevent the build-up of these deposits over time, the cold "mains" water supply is plumbed into the tank-side heat exchange loop above the heat exchanger. A small check valve is located above this entry point. Passive anti-fouling is achieved when the resident of the home opens their hot water tap and draws hot water from the storage tank. This action causes cold mains water to flood into the heat exchanger. Restricted by the check valve, the cold-water flows in the opposite direction through the heat exchanger sweeping any deposits into the bottom of the storage tank and out of the system in the consumed water. Three factors ensure that fouling is eliminated:

1) during routine hot water consumption, the flow direction is reversed, backflushing the heat exchanger.

2) the cold mains water re-dissolves the "inverse soluble salts" that normally deposit on hot surfaces; and

3) the flow through the heat exchanger will often be high sweeping away sediments.

The result is that the heat exchanger is "serviced and cleaned" every time the homeowner consumes hot water. This system has been successfully implemented on thousands of residential solar hot water systems in North America.

To prevent the build-up of these deposits over time, the cold "mains" water supply is plumbed into the tank-side heat exchange loop above the heat exchanger. A small check valve is located above this entry point. Passive anti-fouling is achieved when the resident of the home opens their hot water tap and draws hot water from the storage tank. This action causes cold mains water to flood into the heat exchanger. Restricted by the check valve, the cold-water flows in the opposite direction through the heat exchanger sweeping any deposits into the bottom of the storage tank and out of the system in the consumed water. Three factors ensure that fouling is eliminated:

1) during routine hot water consumption, the flow direction is reversed, backflushing the heat exchanger.

2) the cold mains water re-dissolves the "inverse soluble salts" that normally deposit on hot surfaces; and

3) the flow through the heat exchanger will often be high sweeping away sediments.

The result is that the heat exchanger is "serviced and cleaned" every time the homeowner consumes hot water. This system has been successfully implemented on thousands of residential solar hot water systems in North America.

To Get More Information

For more information on the Passive Anti-fouling System, please refer to the following paper published at the annual conference of the International Solar Energy Society: Stephen, J., Harrison, "Passive Heat Exchanger Anti-Fouling for Solar DHW Systems", Proceedings of ISEC, August 6-12, 2005, Orlando, ISEC2005-76232.

This patented technology will be available for purchase through Neoperl soon.

Licensing opportunities, please contact Robert Stinson at QSBR Innovations Inc.

This patented technology will be available for purchase through Neoperl soon.

Licensing opportunities, please contact Robert Stinson at QSBR Innovations Inc.